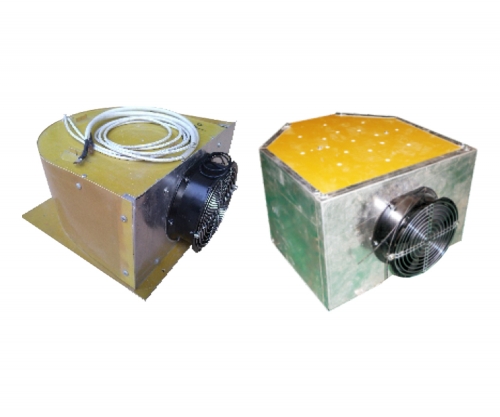

Application of electromagnetic heater in extrusion mould heating furnace

In recent years, customers in the market to ask the electromagnetic heater in the aluminum mold heating more and more, now the domestic customers also continue to add, basically die heating directly choose electromagnetic heating method is more and more throughout, electromagnetic specially developed special aluminum mold electromagnetic heater.

The same electromagnetic heating coil can be used for general purposes from 139mm to 178mm in diameter. When the diameter is 139mm, the input current is about 10 ~ 12A and the power is about 8 ~ 10KW. When the die diameter is 178mm, the input current reaches 16 ~ 18A and 12 ~ 15KW. Able to 8 ~ 12 minutes add mold temperature to 450 ℃. Can be very good to deal with the choice of resistance furnace heating method, because the choice of resistance furnace heating method is difficult to make the mold surface temperature common, so that the mold in the extrusion process of uneven stress, easy to exceed the load, resulting in cracks in the mold bridge useless. Therefore, the production cost of mold is increased, and the resistance furnace has such defects as high power, high power consumption, high repair cost, long preheating time and holding time, and slow heat transfer through air.

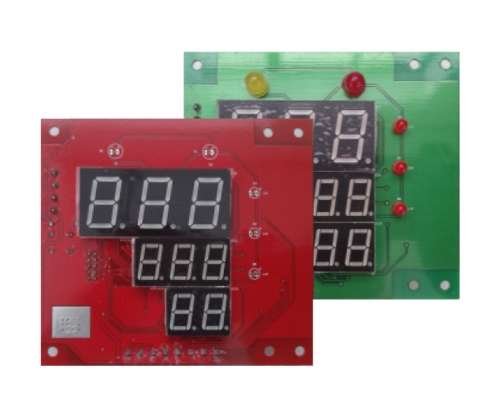

Parameters of mold electromagnetic heater:

1. Purpose: it is used for mold heating (different from the usual pipe heating), similar to the mold heating furnace.

2, apply to ¢130 ~ ¢320 mm aluminium rods moulds (according to the request custom).

3. Heating method: non-contact induction heating.

4, input power: 8 ~ 15KW(according to the size of the mold automatic conditioning, usually when the mold is small, the power automatically adjusted, when the mold is large, the power automatically adjusted).

5. Input voltage: three-phase four-wire system 380V 50/60hz.

6. Vibration frequency: 5KHZ ~ 30KHZ(operating range: 8 ~ 10KHz at high power).

7. Cooling method: air cooling.

8. Thermal efficiency: over 95%.

9. Resonance method: full digital digital phase-locked half-bridge type.

10. Maintenance methods: over current, over voltage and over temperature.

The address of this article:http://liangjialin.cn/en/news/369.html

Key word:模具爐,模具加熱爐,節(jié)能模具爐

The next one:Main technical parameters of single tractor

Recently browse:

Related products:

Related news:

- What are the key selection points when purchasing medium frequency heating furnace equipment?

- Comparison of electromagnetic heater and traditional heating method

- Industrial applications of electromagnetic heaters

- What should I pay attention to when installing the electromagnetic heater

- Where can the electromagnetic heater be applied

- Advantages of household electromagnetic heaters

- How to choose the power of electromagnetic heater?

- How should electromagnetic heating heater maintain?

- How to nurse the daily of electromagnetism heater?

- How much can transform electromagnetism heater save after all?